Adhesives

An adhesive is a substance that is used to bind two separate items together and resist separation. However, depending on the chemical makeup, adhesive products may be used to fill seams or holes, waterproof, laminate, contain liquids or level surfaces. Adhesives are made up of an epoxy and a hardening substance with each compound specially designed with a specific task in mind. One may find a wide variety of adhesives at nearly any store because for each adhesive, the composition is carefully considered to ensure the proper adhesive and cohesive qualities.

Adhesives are used in a wide variety of engineering and manufacturing purposes in large quantities, and for a wide range of uses. Some of the ingredients used in creating adhesives are casein, starch, natural rubber, butyl rubber, amino resins, polyurethane, polyvinyl acetate, acrylates, silicones and more. Adhesive suppliers work with a multitude of chemical solutions to ensure their custom adhesive will perform the tasks efficiently.

Quick links to Adhesives Information

History and Evolution of Adhesives

The first evidence of human use of adhesive bonding was confirmed when two stones were found bonded together by birch-bark tar in central Italy. The materials dated back to the Middle Pleistocene era (circa 200,000 years ago). As humans began learning about compounding chemicals to ensure longer lasting bonds in their products, adhesive and sealant solutions became one of the first discoveries crucial to the creation of our first rudimentary tools. In 70,000 BC, Native Americans in South Africa, used a gluey substance made of tree sap and red ochre to seal their cave paintings. Following them, in 2,000 BC Egyptians used liquid glue to create their wooden artifacts. This liquid glue was created from animal remains and can still be found in their artifacts found in the tombs of the Faraos. In 1700, the first industry opened and produced liquid adhesives commercially in Holland. In 1932, America's food and beverage company Borden, created Elmer's All-Glue. With the creation of synthetic and plant based glues the use of animals during commercial adhesive production started disappearing as new rules and regulations were put in place to protect animals. However, casein from milk proteins and other animal products are still used. In 1947, the first PVA-based adhesive was created and sold by Casco.

Now researchers are striving to develop adhesives utilizing Nanotechnology to mimic the behavior and adaptations of the gecko reptile. If this is actualized, it will recreate the same molecular behavior that geckos use on their feet to "stick" to a surface. As research progressed, adhesives have developed from its crude beginnings to include vinyl plastisol, diglycidyl ether, adhesive tapes, thermally conductive adhesives, construction adhesive, plastisol pvc and more.

There are scant few products left that do not rely on the integrity of adhesive manufacturers products. As time passed, the chemical compounds of our adhesives have changed, but the importance and impact of a well-made adhesive has not.

Benefits and Advantages of Adhesives

- Structure and Bonding Benefits

- The benefits and advantages of choosing adhesives as a bonding agent rather than utilizing hardware or mechanical forces, are simple. Because of the variations of adhesives available on the market today there is always a way to find the right fit for the job. The adhesive or sealant is able to bond the two surfaces together without sacrificing the structure of the item, or the material in which it is composed.

- Adhesive Appearance Advantages

- Adhesives require little/no heat, unlike welding, making it safer to use and less likely to damage an item. Adhesives are also easily hidden from view, so there is no need to sacrifice the design of an item. Adhesives are flexible and reliable in their service to the industrial field. As if that weren't enough, adhesives and sealants offer more than only bonding, they are used to insulate and level items as well, making adhesives another tool for mechanical use.

- Multiple Adhesive Options

- When it comes to the materials used, there are three main categories of industrial adhesives: silicone adhesive, acrylic adhesive and polyurethane adhesive. When classifying these compounds, one takes into account their adhesive properties, curing mechanism and composition. The curing mechanism is the way an adhesive is utilized to harden. For example, hot melt adhesives require heat to cure, while other ultraviolet adhesives utilize sunlight to harden. There are also pressure sensitive adhesives that attach when pressure is applied. Some adhesives have the ability to conduct heat and electricity like the type utilized on a touch screen. The possibilities and flexibility of the adhesives offered today are seemingly endless. As each compound becomes more specialized, the number of adhesive products grows as does the difficulty of finding the exact match to meet an individual need.

- Adhesives can make or break any product. Whether you’re sealing floors and counters, pasting labels or creating auto components, knowing what sealants options are available and which to choose can mean the difference in a satisfied client, consumer or employer. Industrial adhesives and structural adhesives have been a crucial tool for humankind for over 200,000 years and will remain a staple in manufacturing products. It is the responsibility of an adhesive glue manufacturer to present all options available and meet a client’s adhesive needs. Whether a job calls for a pressure-sensitive adhesive, water-soluble polymer or sealants the right manufacturer will provide the right products.

Uses and Applications of Adhesives

Adhesive manufacturers create custom industrial adhesive products for bonding a wide variety of applications. Industries such as woodworking, plumbing, packaging, labeling, appliance assembly, automotive, engineering, construction, clothing assembly, book binding, and more, all use a multitude of adhesives and sealants each with a solution designed to provide the strongest bond and the most reliable seal. Epoxy adhesives are the most resistant and toughest adhesive compound today with uses such as fiberglass repairs, carpentry and woodworking, wood and metal fillers, jewelry making and even to reinforce bolts. Nearly every setting, from your cupboards at home, the desk in the office or the upholstery in the plane taken to visit distant family has been constructed, adorned or composed of an adhesive.

To accompany the various forms of adhesive are an array of applicators. Beyond the basic glue gun or dispensers are brushes, spray guns, roller coaters, curtain coaters, caulking guns and air actuated models. There are more applications of adhesives and sealants than can be named and the applications grow each year. Some of the lesser-known applications are medical care endeavors such as wound care, medical device creation and implantation, wearable sensor adhesion, transdermal adhesives and laminates and device mounting. These products would include the sticky pads on an EKG, the adhesive used in medicinal patches, and even the fast-acting adhesive used to stop the bleeding of a deep wound. The application of adhesive in mobile devices include grounding and shielding, general assembly, display bonding and protection, and electrical interconnection security. Each phone on the market, regardless of manufacturer or brand, has been assembled utilizing adhesives and sealants. The automotive business relies on adhesives for LED lighting, labels, gaskets, structural and interior bonding, side mirrors and more. It is apparent that there is not a moment of the day when we, as a society, do not rely on the dependability and flexibility of our adhesive industry.

Adhesive Images, Diagrams and Visual Concepts

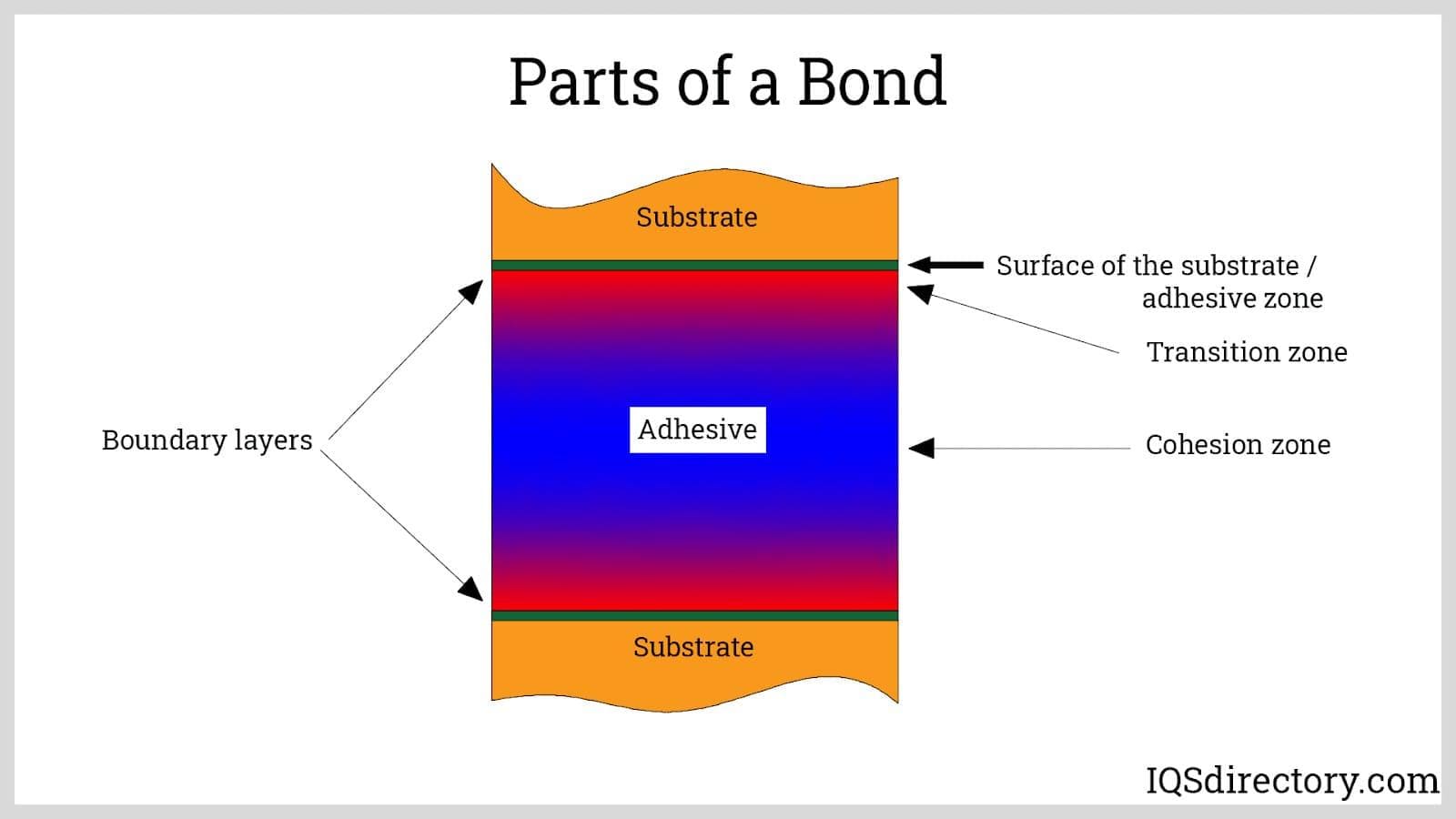

The different parts and layers of an adhesive bond

The different parts and layers of an adhesive bond

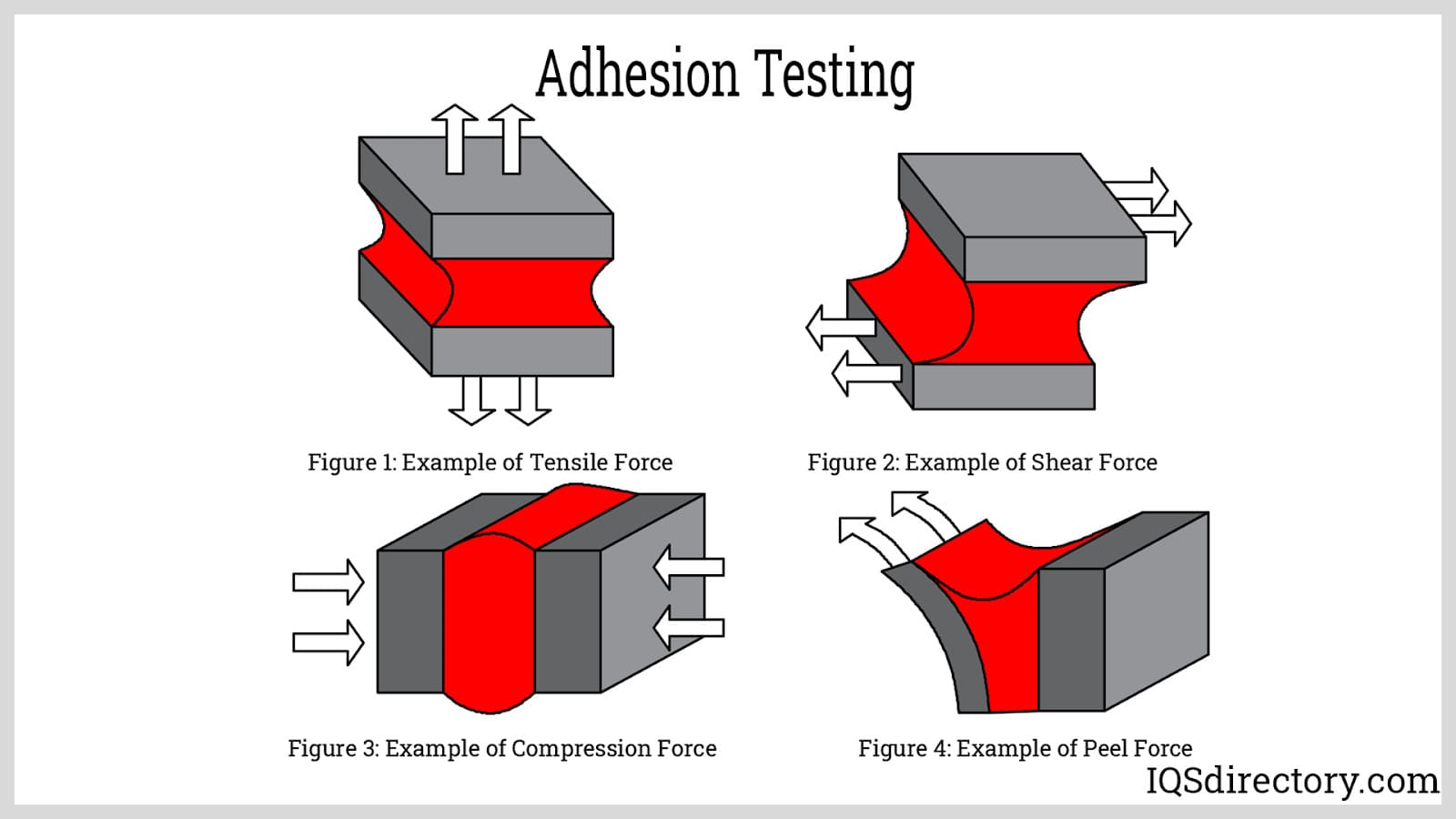

Tests for comparing relative qualities of the adhesive.

Tests for comparing relative qualities of the adhesive.

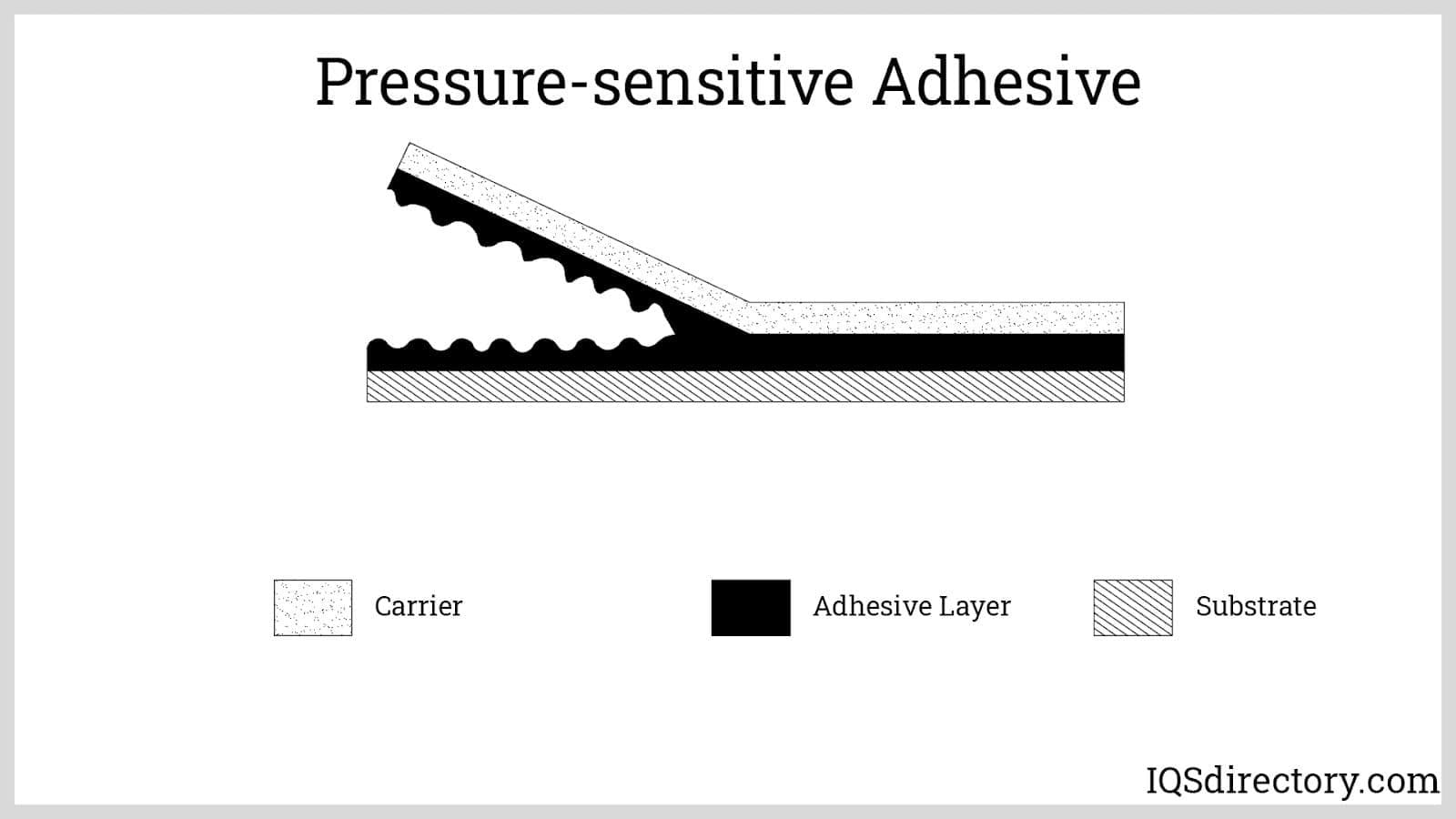

Using pressure to establish an adhesive bond.

Using pressure to establish an adhesive bond.

Adhesive must "wet out" the surface to be bonded for optimal adhesion and covers a surface in order to increase the contact area and attractive forces between the adhesive and the bonding surface.

Adhesive must "wet out" the surface to be bonded for optimal adhesion and covers a surface in order to increase the contact area and attractive forces between the adhesive and the bonding surface.

Silicone adhesives are durable, weathering resistance, waterproof, impact resistant, does not crack or peel, and makes a flexible bond.

Silicone adhesives are durable, weathering resistance, waterproof, impact resistant, does not crack or peel, and makes a flexible bond.

Adhesive Types

- Acrylic Adhesives

- And acrylate adhesives offer fast bonding at room temperature and are highly resistant to environmental conditions. They are able to stick to oily surfaces and many types of materials, including most metals, plastics, glass, ceramics and wood.

- Adhesive Manufacturers

- Companies that produce adhesive products and adhesive accessories.

- Aerosol Adhesives

- Industrial spray adhesives that offer convenience and effectiveness for general purposes, such as foam and fabric, upholstery, screen printing, labeling, palletizing, trim and laminating, high bond high strength, high strength fast tack, pressure sensitive repositionable and temporary or permanent bond applications.

- Anaerobic Adhesives

- Cure in the absence of oxygen. Curing is catalyzed when bonding with surfaces where metallic ions are present.

- Conductive Adhesives

- Or electrically conductive adhesives, offer electrical and/or thermal conductivity between components.

- Cyanoacrylate Adhesives

- Fast setting adhesives commonly referred to as “crazy glue.” Only a small amount of these one-component adhesives are necessary to form a rigid plastic layer that has high strength.

- Epoxies

- Or epoxy resins, are raw materials that can be formulated to make paints, coatings or adhesives.

- Epoxy Adhesives

- Very strong and highly resistant to heat and chemicals. They can be formulated to be either flexible or rigid, transparent or opaque, fast setting or slow setting. All these characteristics make them appropriate for nearly all uses.

- Hot Melt Adhesives

- Or thermal adhesives, are viscous liquids at elevated temperatures that generally set quickly when cooled. Types include fast set, delayed set and pressure sensitive. Common uses include bookbinding, product assembly and box and carton heat sealing.

- Industrial Adhesives

- Bonding products specifically designed for manufacturing environments.

- Laminating Adhesives

- Substances that are used for bonding in thin layers. They come on sheets of release paper that are wound in rolls to be used in lamination presses or applied by hand with a plastic squeegee or hand roller. The liner is then removed from the adhesive.

- Methacrylates Adhesives

- A newer form of adhesive technology developed to offer superior performance compared to acrylic adhesive, which can be brittle and less reliable. Methacrylates provide good gap fill, excellent impact resistance, flexibility and peel and shear strengths, medium to fast curing, and tolerance of dirty surfaces.

- Membrane Press Adhesives

- Used in membrane press operation. They are heated to the proper temperature for lamination in the press and then quickly set for the unloading and trimming of the piece.

- Moisture Cure Adhesives

- React with moisture in the air or the bonding substrate to form a cured polymer layer with high strength. Silicone and polyurethane are the most common.

- Polyurethane Adhesives

- Come as two-part formulas or pre-mixed, which need to be mixed very well to give the best quality tough yet flexible bonds that they can. They can form strong bonds to most materials and are more flexible than epoxies.

- Pressure Sensitive Adhesives

- Pressure induced tacky materials that bond two flat surfaces together. This adhesive can be coated onto fabric, plastic or metal, and then stuck to another flat surface of metal, plastic, wood and paper.

- Silicone Adhesives

- Can create a permanent seal between two surfaces, also working as a watertight sealant and surface lever when necessary.

- Thermoset Adhesives

- Can not be softened with heat once they are set. Thermoset materials include epoxies, polyesters, silicones, rubbers and polyurethanes.

- Two-part Adhesives

- Consist of two or more components that react to become chemically cross-linked. Their higher costs are related to their extremely high bond strengths and exceptional performance, such as epoxies, polyurethanes, acrylics, and silicones.

- Ultraviolet Adhesives

- Used to seal or bond objects together through a curing process. Fiber optics and dentistry both use this adhesive.

- Urethane Adhesives

- Bond with a wide range of materials and are tough and flexible at low temperatures but weaken due to high temperatures and contact with moisture.

- Water-based Adhesives

- Or aqueous adhesives, use water as a carrier or diluting medium. They set when the water evaporates or is absorbed by the substrate.

Adhesives Production Process

To produce the right compound, manufacturing companies must answer a lot of questions about the circumstances the adhesive will be performing under. Will the adhesive be under pressure? Will there be oxygen available for the adhesive to cure? Will the adhesive be at room temperature? Will the compound be exposed to extreme heat, prolonged sun, wind, or ice? Does the material need to bend?

To meet these demanding needs, adhesive products are offered in a wide variety, each designed with their bonding application in mind. Some of the more basic qualities a manufacturer must ensure in any adhesive is that of mechanical bond. For an adhesive to bond two surfaces, a lot of interactions have to take place between the product and the surfaces in play. First, the product must be able to spread over the surface of the item being bonded. For this to occur, the product needs to have a lower viscosity so that it is able to spread over the surface. Viscosity is the resistance to flow. For example, rain has a low viscosity allowing it to pour and drip, whereas lava has a higher viscosity causing it to billow and mound. Because viscosity can be impacted by temperature, utilizing a colder product, or a colder surface, may impact the ability of the product to spread and so has to be taken into consideration when creating the compound.

Another factor that affects the compound's ability to spread is the relative strength of adhesion. If the cohesive strength among adhesive molecules is not as strong as the adhesive strength between the adhesive molecules and the surface of the item to be bonded, then the compound will spread over the surface. A compound that is relatively low viscosity while being able to spread over the surface, the compound will flow into any tiny fissures or pores on the surface and create mechanical bonding. The mechanical bond greatly increases the strength of an adhesive bond.

Adhesives can have differing setting temperatures ranging from above 212º F to below 68º F, depending on how much they need to be cooled or dried to harden. For example, hot melt adhesives are activated to viscous liquid states at elevated temperatures and set when cooled. Adhesives have various setting speeds, some remaining tacky for a certain amount of time, which allows more time for parts to be assembled. You can find hot melt adhesives here on IQS Directory.

There are a wide variety of adhesive types. Adhesives may be created as a one-part or two-part formula. Two-part adhesives have two separate compounds that need to be mixed well. They may also be utilized to separate adhesives and pressed together to form a chemical reaction. This process leads to the separate compound bonding. This is the case for epoxies, acrylics and urethanes. Other adhesives require homogenous mixing to activate the chemicals within, so they require mixing only moments before application. On the other hand, one-part adhesives have latent bonding. They are activated by energy drawn from outside of the compound. The source (heat, oxygen, moisture, radiation or pressure) depends upon the type of adhesive at work. Most adhesives have differing cure-time methods. For example, some super glues dry almost instantly, while other adhesives like a wood glue, will need to dry over a night or two before it is completely set-up.

Manufacturers offer adhesive solutions in foams, films, pastes, liquids, solids, seal tape, powders and even aerosol sprays. Solid adhesives or sealants are further varied in form of melt sticks, granules, chips and pellets. Each of these products require specific processing to acquire the desired effects. However, each adhesive product is measured in similar aspects including, impact strength, cleavage strength, fatigue strength, tensile strength, shear strength and peel strength. Each adhesive compound is designed with their cure time, substrate surface, high ductility, mechanical bonding, and water molecules in consideration, to ensure the engineers and manufacturers that rely on them get the adhesive sealant that is right for the job.

Adhesives Terms

- Adhesive

- A substance that is resistant to adhesion and can be used as a non-sticky surface coating for baking tins, frying pans, metal pots, etc. Examples are Teflon and silicone.

- Adherend

- Something bonded to something else through the use of an adhesive.

- Cleavage Strength

- How crack resistant a bonded adhesive is when stretched and strained.

- Curing

- Hardening or solidifying by cooling, drying or crystallization. Also referred to as setting.

- Curtain Coating

- Covers large areas with a relatively heavy coating of adhesive. Parts are passed through a “waterfall” of coating in an automated conveyor line.

- Encapsulant

- Can be an adhesive coating that hardens to form a protective layer to prevent degradation of whatever it encapsulates, such as electronic components.

- Fatigue Strength

- The maximum load an adhesive bond will sustain when subjected to repeated stress.

- Impact Strength

- An adhesive’s ability to resist shock from a direct perpendicular physical blow.

- Peel Strength

- A measurement of the bond strength of an adhesive determined by the force per unit width required to separate bonded materials by applying stress in a “peeling” motion.

- Release Paper

- An easily removable protecting and/or carrier sheet for certain adhesives, commonly film and laminating adhesives.

- Resins

- Thick, sticky hydrocarbon plant secretions great for varnishes and adhesives.

- Roll Coating

- A method for applying adhesive, the simplest form of which is using a paint roller, but usually the coating rolls are part of a roll coating machine that precisely controls layer thickness, does not allow waste and is good for large surfaces at high speeds.

- Screen Printing

- A method of applying adhesive in specific patterns by way of forcing it through a screen using a squeegee. The size of the screen openings determines the coating thickness.

- Shear Strength

- How resilient a material, such as a cured adhesive, is to a parallel stress acting upon it, which can cause an irreversible continuous, non-fracturing deformation.

- Substrate

- The material surface upon which an adhesive is spread for bonding or coating. More specifically adherend.

- Tensile Strength

- A measurement of an adhesive’s bond strength based on how resistant it is to tension, being stretched and strained.

- Transfer Printing

- A fast method of applying a thin layer of adhesive in a precise pattern, such as on envelope flaps. Usually done using rollers; flat plates can also be used.

- Wet Strength

- An adhesive’s bond strength immediately after it has been immersed in a liquid under specified conditions of time, temperature and pressure.